HAVE YOU EVER bought or used paint? What about flour, tires, paprika, chocolate, vitamins, makeup, pet food, crayons, fertilizer? If you have, then you are indebted in no small measure to the size reduction industry for these products. But what is that exactly?

then you are indebted in no small measure to the size reduction industry for these products. But what is that exactly?

At its most basic, the term ‘size reduction’ is applied to the processes in which particles of solids are cut or broken into smaller pieces. “Here at the Pulva Corporation, we produce size reduction mills that take, for example, granulated sugar down to a powdered sugar,” states Pulva Vice President Catie Morley. “We sell our machines to the pharmaceutical , pigments, plastic, chemical, and food industries. We also support them through their processing whether it's with parts or service or whatever they need.”

It is a sizable (no pun intended) industry with applications from the gargantuan to the domestic, everything from the This Old House video we’ve all seen of multi-ton boulders shattered into gravel, all the way down to the coffee-bean grinder sitting on your kitchen counter.

It’s Hammer Time

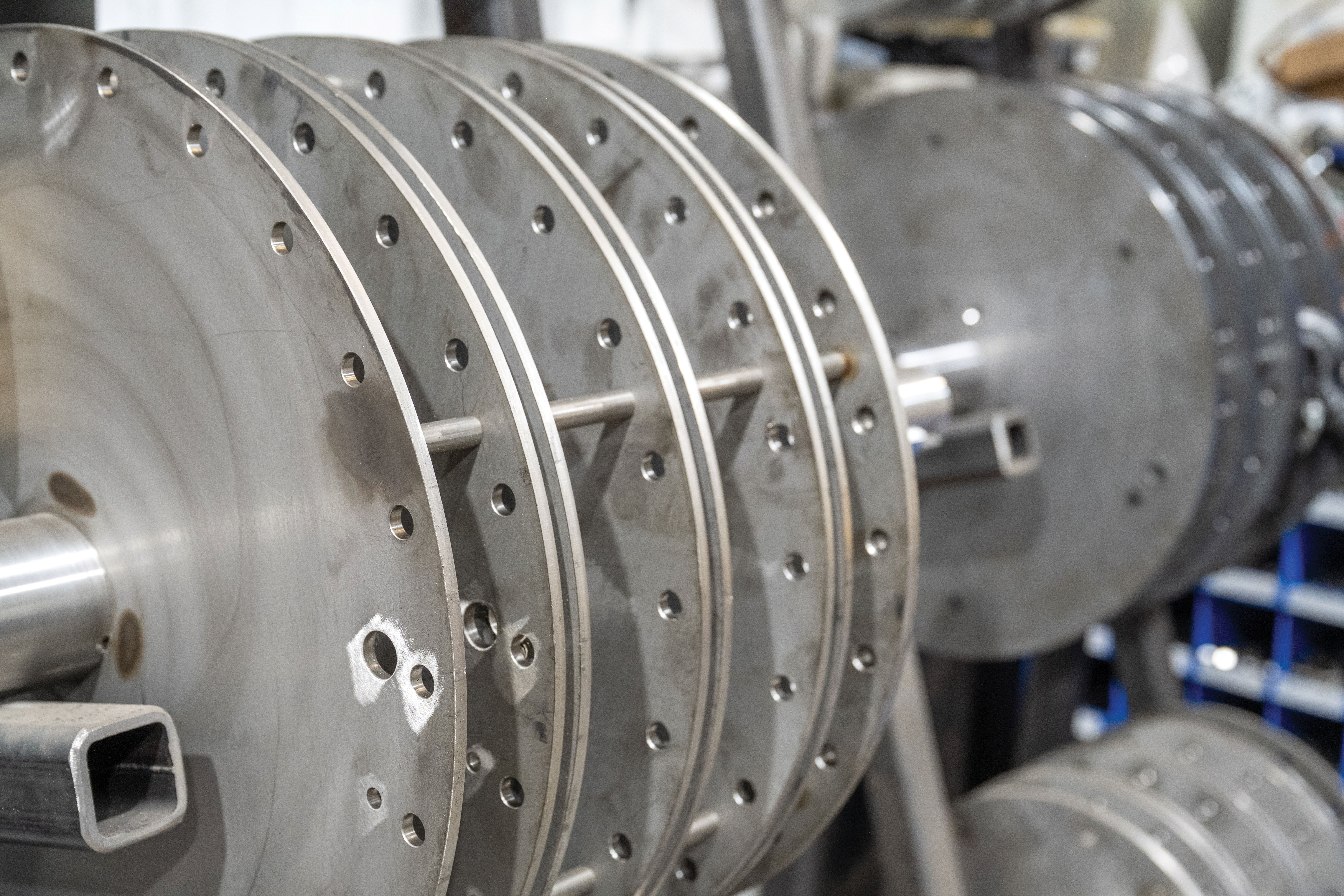

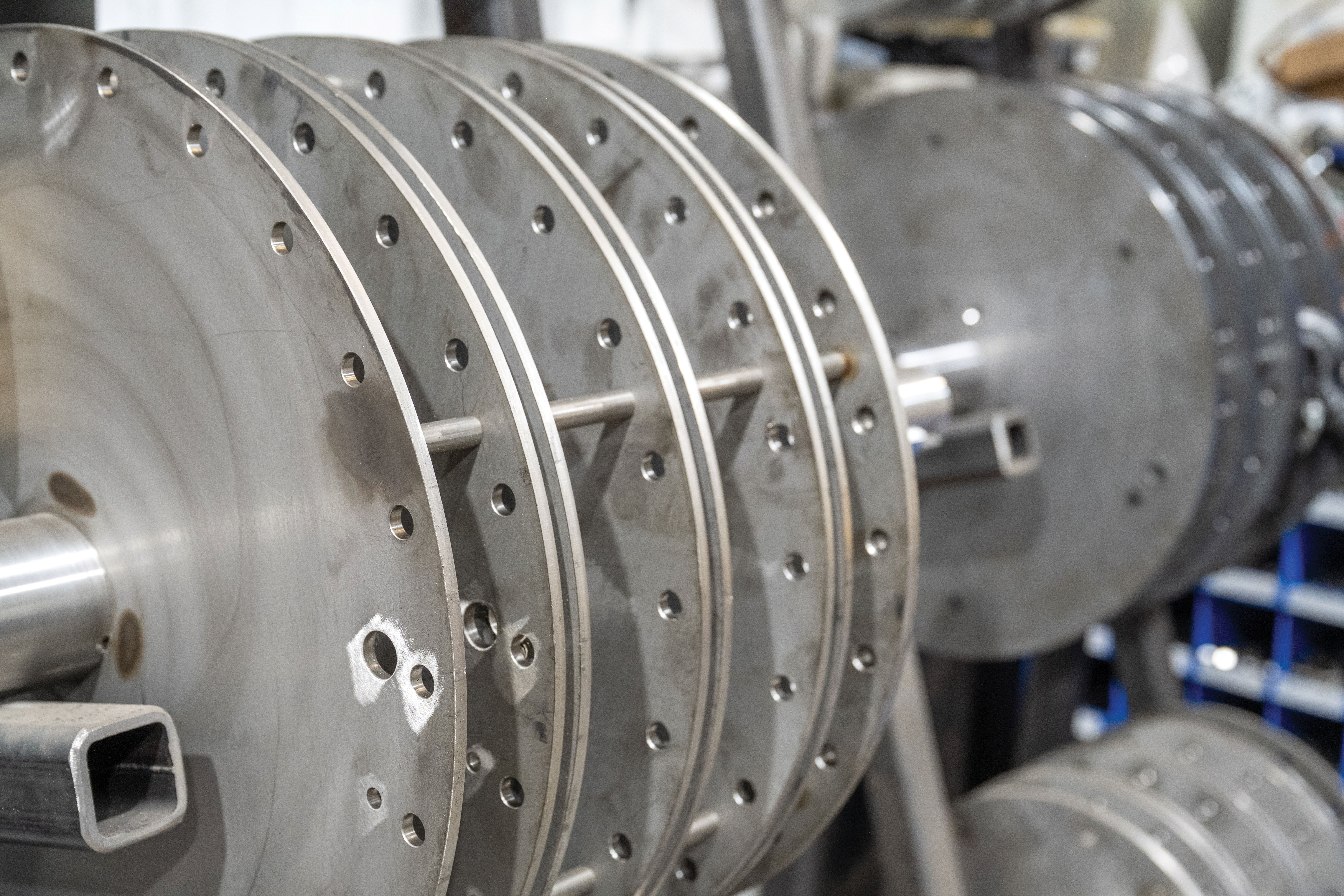

Pulva, headquartered in rural Valencia, Pennsylvania, produces and sells a complete line of particle size reduction technologies for a wide expanse of materials and capacities. Their aptly named hammer mill grinders are impact-type grinding mills that employ the use of hammers.

expanse of materials and capacities. Their aptly named hammer mill grinders are impact-type grinding mills that employ the use of hammers.

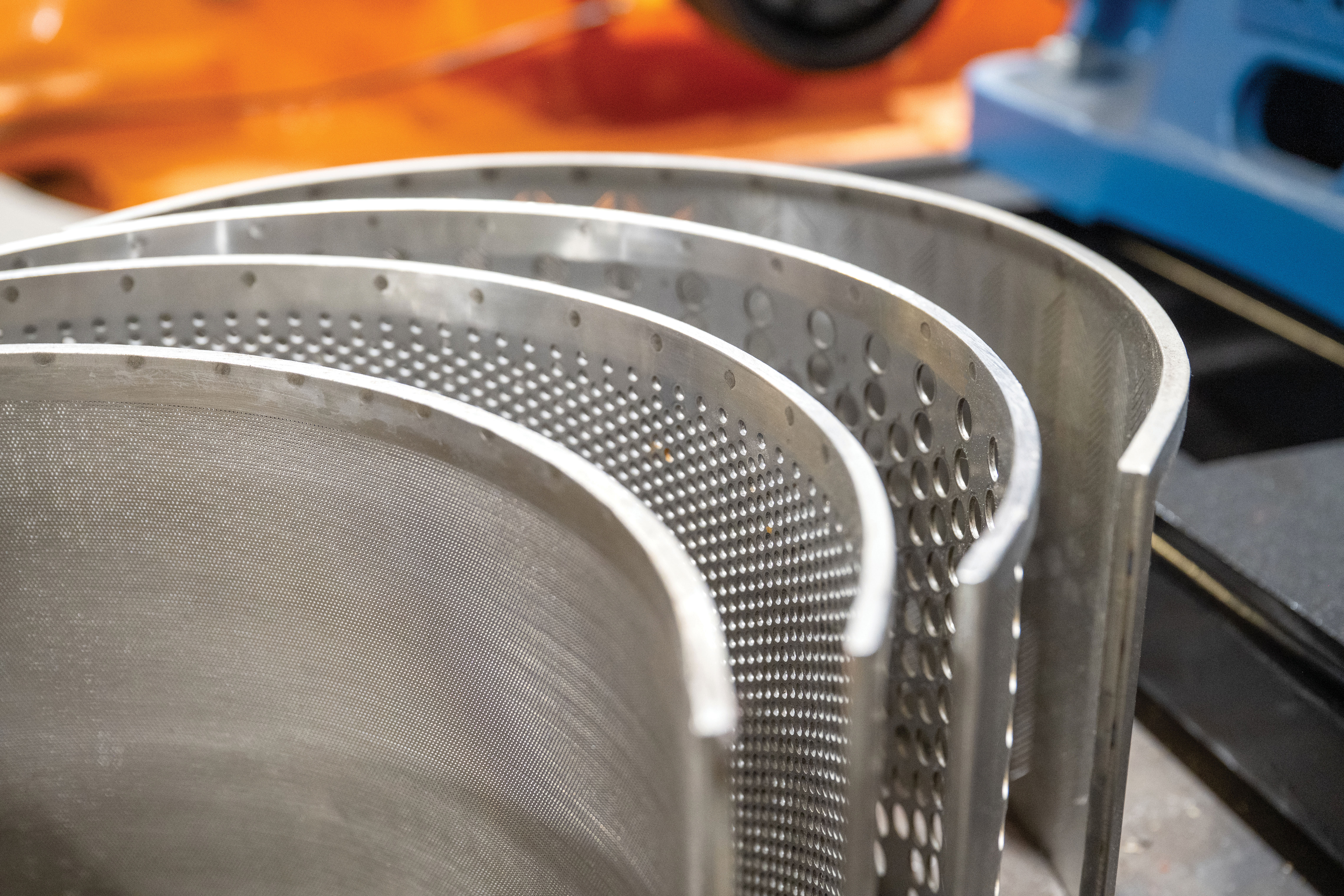

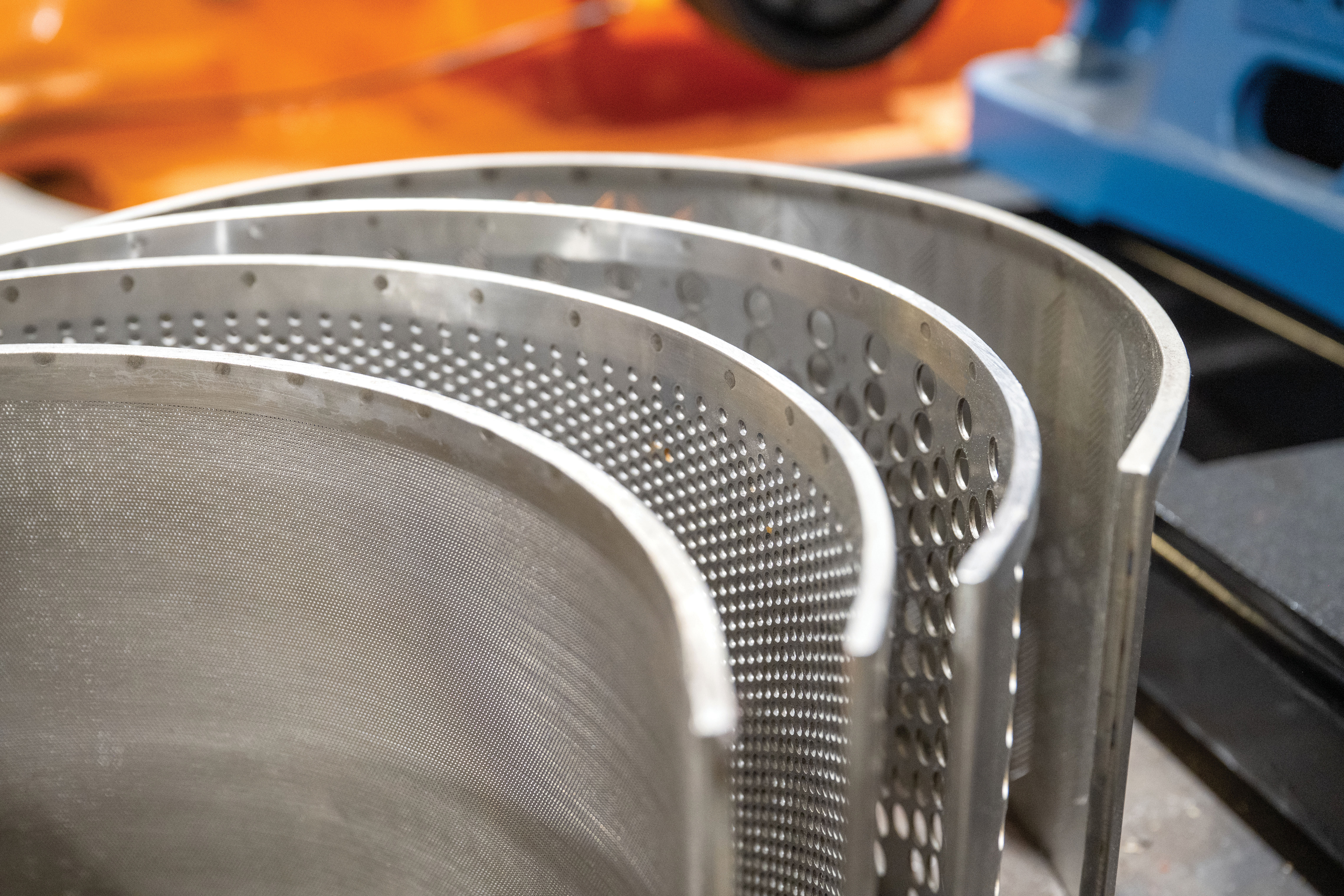

For a little deeper dive, hammer mills work on the principle that most materials will crush, shatter, or pulverize upon impact. Specific base material (cocoa beans, wood chips, rubber) is fed into the mill’s chamber via a feed chute. Once inside the chamber, the material is struck by rows of hammers connected to a high-speed shaft that rotates inside the mill’s tightly enclosed grinding chamber (their Pulvette model rotates at 14,000 rpm). Repeated hammer strikes, along with particle-on-particle impacts and the fluted inside cover directing particles back into the hammer path, quickly reduce the material. Screens at the mill’s bottom allow the smaller particulate to pass through, while larger pieces, swept up by the hammers’ centrifugal motion, are quickly reduced.

Rooted

Speaking with the Ferree family, owners and managers of the Pulva Corporation (and quite a few others), is to understand their drive in

keeping the quality up. “Well, both our grandfathers were business owners, and dad of course,” Ferree family member Catie Morley recalls. “Our aunts and uncles are business owners and our grandmother was a business owner. So, the entrepreneurial spirit is pretty deeply rooted in us.”

Regarding their father, a man of more than one hat (or helmet, as needed), businessman Ed Ferree is a former American professional stock car racing driver who competed in the 80’s and 90’s in the NASCAR Winston Cup Series and the Busch Series. No stranger to diligent effort, Ed nonetheless is grateful for his family, workers, and clients. “I grew up in my dad’s companies, learning from him and his associates, both their successes and failures,” Ed Ferrree states.

How it all Started… And Continues

Ed Ferree purchased Pulva in 1988 from Fred and Mary Kolisek, who had operated the company out of Perth Amboy, New Jersey, and installed it in an existing Valencia, Pennsylvania structure the Ferree family owned. Ed worked with his entrepreneurial father, Roy, who previously started and operated ESM, a company that ground magnesium, and was familiar with the industry. Bringing a sharp business acumen and work ethic (learned at his father’s side, and passed on), Ed built the original 5,000 square feet of what is now Pulva’s sizable facility in 1991. The original structure has been added on to again and again, as the need arises. And, with this family, the needs do arise.

Ed Ferree purchased Pulva in 1988 from Fred and Mary Kolisek, who had operated the company out of Perth Amboy, New Jersey, and installed it in an existing Valencia, Pennsylvania structure the Ferree family owned. Ed worked with his entrepreneurial father, Roy, who previously started and operated ESM, a company that ground magnesium, and was familiar with the industry. Bringing a sharp business acumen and work ethic (learned at his father’s side, and passed on), Ed built the original 5,000 square feet of what is now Pulva’s sizable facility in 1991. The original structure has been added on to again and again, as the need arises. And, with this family, the needs do arise.

The first addition provided a laboratory where Pulva technicians can gauge the preciseness of a specific grind that a prospective purchaser requires. Again, this was just the start. As Catie states, “We call our dad a ‘serial entrepreneur.’ He’s constantly looking for new things.” Pulva marketing head (and Ed Ferree’s daughter) Aimee Miller adds, “Our dad is, I would call it, a ‘process fixer.’ If he sees a process that could be fixed, he's going to do it. But manufacturing is kind of the core that keeps all of these things together.”

“All of these things” refers to the many Ferree Family Businesses (FFB) offshoots that the Ferree family has acquired over some decades (See the accompanying sidebar story for a rundown of all the businesses they operate). Some relate to one another, and some don’t. In 1990, Ed, for example, given his penchant for racing, bought Frankland Racing, which repairs and rebuilds Late Model, Modified, Sprint Car, or Street Stock quick-change rear ends for oval track racing.

Tight-knit

You hear many businesses talk about business as family, but there is a reason the companies are called Ferree Family Businesses. Catie’s husband Brian is a manufacturing coordinator, Caroline’s husband Dave Hahn works as an application engineer, and Alex’s wife Brenda is an accounting clerk.

Their mother and Ed’s wife, Gayle Ferree, works there also. The family purchased water conditioning company Watersoft in 1980, “and I’ve been running it since,” Gayle states. “I also enjoyed farming, flying and racing with Ed, the girls and Alex. It’s been enjoyable watching my children take over the businesses and seeing them work alongside Ed and me.”

That’s just their family. “It's kind of crazy the amount of relatives of other families we have working for us. One employee, Dave, his son and his nephew work here. There are also two brothers, a husband and wife, another father and his son, and two sisters,” Catie states. “But, that’s how tight-knit Western Pennsylvania is.”

You can Bank on Farmers

As business owners know, you will eventually require the assistance of an understanding bank. The Ferree Family Businesses, as a growing business, know this well. “We've done some new business loans for the acquisitions that we've completed, such as Marvel Marking and Sutton International,” explains Catie. They also work with Farmers for their day-to-day banking, utilizing the bank’s online platforms, and in person via the Bon Aire Plaza location in nearby Butler.

business, know this well. “We've done some new business loans for the acquisitions that we've completed, such as Marvel Marking and Sutton International,” explains Catie. They also work with Farmers for their day-to-day banking, utilizing the bank’s online platforms, and in person via the Bon Aire Plaza location in nearby Butler.

Josh Fye, Vice President, Commercial Banking Team Leader at Farmers, says, “As Mr. Ferree grew his businesses over many decades with Farmers National Bank of Emlenton, we are grateful to have the opportunity now as Farmers National Bank of Canfield to continue to support the transition to the next generation of the Ferree family. While continuing with our commitment to serve the communities, we are prepared to assist Ferree Family Businesses with their expansion and growth objectives.”

Flexible

A typical day at Ferree Family Businesses is alike and unlike most other companies. Alike, in that a job has to get done and done right, which they certainly do here. Decidedly unlike, in that with seven companies under one roof, some sharing similar elements and others not, a degree of teamwork among their 86 employees is just the order of the day here.

“Everybody has a varying schedule,” Alex Ferree states. “We have a couple of people with outside circumstances, family circumstances, that change their schedule quite a bit. We’re just flexible for them.” Aimee Miller adds, “I think it is appreciated because when we need something done, or you know if it's outside someone’s job description, our team goes above and beyond to get it done.”

“The World.”

Sales manager Brad Gray has been with Pulva for ten years. Among his sales duties, he is constantly on the lookout for new accessories that, as he states, “Go with our equipment or things we can engineer to make our equipment better.”

Gray has honed his sales focus, itemizing his priorities over a decade in the industry. Most important? “The biggest thing is just having a good relationship with the customers, knowing their priorities, getting out to see them and letting them know that we are here when they need us.”

An interviewer can, upon occasion, offer up a question and be startled by a wholly unanticipated response. Answering a stilted inquiry

about the ‘region’ Pulva serves, Gray provides a surprising yet, to him, matter-of-fact reply, “I mean, it really depends on your definition of ‘region.’ We service the world.”

Values are at the Heart

“As I built my own companies, trying to apply the best ideas of my dad and his colleagues, my children were exposed to the conviction of doing the best for our employees and customers,” Ed Ferree states. The result is everything an entrepreneurial father could wish for in the ensuing generation, “Carrying on what our parents started is both an honor and a big responsibility,” says Catie Morley. “We were lucky to grow up watching their example: grounded in hard work, faith, and caring for people. Now, as we take the lead, our goal is to keep those same values at the heart of everything we do.”

then you are indebted in no small measure to the size reduction industry for these products. But what is that exactly?

then you are indebted in no small measure to the size reduction industry for these products. But what is that exactly? expanse of materials and capacities. Their aptly named hammer mill grinders are impact-type grinding mills that employ the use of hammers.

expanse of materials and capacities. Their aptly named hammer mill grinders are impact-type grinding mills that employ the use of hammers. Ed Ferree purchased Pulva in 1988 from Fred and Mary Kolisek, who had operated the company out of Perth Amboy, New Jersey, and installed it in an existing Valencia, Pennsylvania structure the Ferree family owned. Ed worked with his entrepreneurial father, Roy, who previously started and operated ESM, a company that ground magnesium, and was familiar with the industry. Bringing a sharp business acumen and work ethic (learned at his father’s side, and passed on), Ed built the original 5,000 square feet of what is now Pulva’s sizable facility in 1991. The original structure has been added on to again and again, as the need arises. And, with this family, the needs do arise.

Ed Ferree purchased Pulva in 1988 from Fred and Mary Kolisek, who had operated the company out of Perth Amboy, New Jersey, and installed it in an existing Valencia, Pennsylvania structure the Ferree family owned. Ed worked with his entrepreneurial father, Roy, who previously started and operated ESM, a company that ground magnesium, and was familiar with the industry. Bringing a sharp business acumen and work ethic (learned at his father’s side, and passed on), Ed built the original 5,000 square feet of what is now Pulva’s sizable facility in 1991. The original structure has been added on to again and again, as the need arises. And, with this family, the needs do arise. business, know this well. “We've done some new business loans for the acquisitions that we've completed, such as Marvel Marking and Sutton International,” explains Catie. They also work with Farmers for their day-to-day banking, utilizing the bank’s online platforms, and in person via the Bon Aire Plaza location in nearby Butler.

business, know this well. “We've done some new business loans for the acquisitions that we've completed, such as Marvel Marking and Sutton International,” explains Catie. They also work with Farmers for their day-to-day banking, utilizing the bank’s online platforms, and in person via the Bon Aire Plaza location in nearby Butler.